Power and passion drives a unique Honda CR500 build that will blow your mind.

Labelled the baddest man on the planet, Mike Tyson, was famously once quoted, “Everyone has a plan until they get punched in the face.” I often think of this when people start talking about Honda’s almighty CR500. This is a bike that captivates riders across the planet because in my opinion, it is the Mike Tyson of dirt bikes. Everyone wants to ride one, until they get offered the chance.

The CR500 sure does carry a reputation and it is well deserved. Ceasing production in 2001 due to low demand, the CR500 has gained a cult following in the years since and is now a highly sought-after bike amongst passionate two-stroke fans. This bike produces eye-watering amounts of power but they are known for being a handful and rather challenging to corner and stop.

This has led to many transplanting the mighty CR500 donk into a modern CRF alloy frame. Service Honda in the USA is world renowned for producing immaculate CR500AF’s and they set the standard for this style of CR500. A Service Honda is a great option if you want to pay for a bike and have it ready to go, but for Jordon Evans, he wanted his alloy frame CR500 to be one of a kind. Jordon Evans tells us the story.

500 FASCINATION

It all started when I was in Year 10 when I saw a YouTube clip of a Yamaha YZ500 fuel-injected two-stroke. Just the sound of it made me think, “hooly-dooly.” And I have had a special interest in them since. Up until then I didn’t know about 500cc two-stokes because I was born in the new four-stroke era. Then one day, during a depressed stage of my life, I decided I needed something to distract me, so I went in head-first and began building the CR500 I wanted.

I started the project in May 2018 when I bought a non-rolling 2008 CRF250R frame with subframe, forks, swingarm, airbox, brake system and triple clamps. I couldn’t use the swingarm or the forks because they were trashed so I found another swingarm and forks then set about sourcing the rest of the parts.

It took a lot of research to figure what I needed and where to get the parts. I spent a lot of time on Facebook groups like CR500 conversion pages and I talked with AJ Waggoner who is the bloke that started the Service Honda 500s. He is the GOAT of 500AFs.

CHALLENGING START

The most challenging part of the entire build was sourcing the engine. They’re difficult to find because they’re just not in high quantities at decent prices in Australia. I was lucky to find a 1989 model engine, even though people considered the price outrageous at the time, but it was the cheapest I could find.

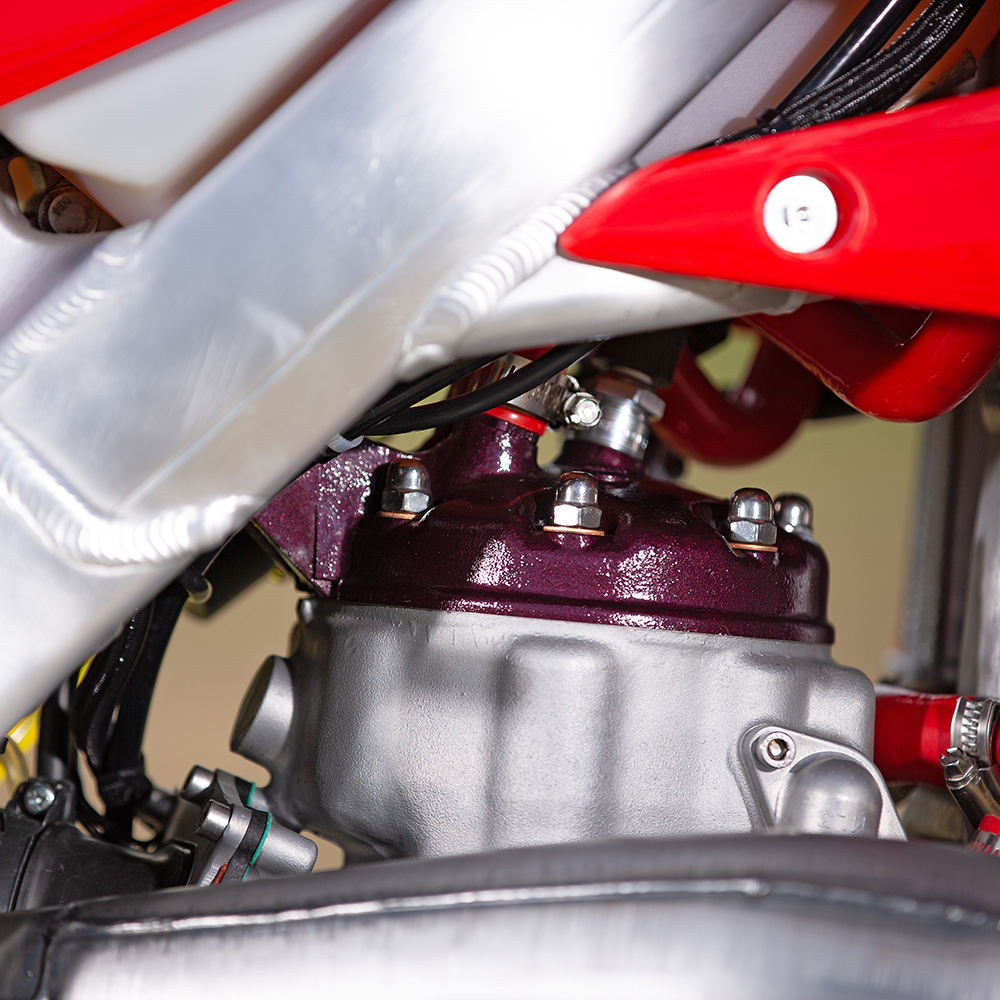

The airbox was a challenge because I needed to mate the original CRF airbox to the 1998 CR250 airboot and cage with an adaptor plate that does come with the conversion kit I purchased. The process of actually putting this together was scary. A bit like heating the brand new Acerbis fuel tank to re-mould the under-side allowing clearance for the sparkplug and coolant hoses. I was scared about putting a hole in it or making it too thin, but it worked out perfect.

There were countless things that made this build tough. I ended up making my own vapour blasting cabinet after getting prices for someone else to clean up all of the aluminium parts for me. I built one for less and now have my own vapour blasting cabinet for future projects. But that was a three-month project on its own.

I knew this was going to be a long process and I was prepared to take my time with it to get it right because I didn’t have any specialty tools. I only had a normal tool kit so I needed to acquire some new tools.

HARD PARTS

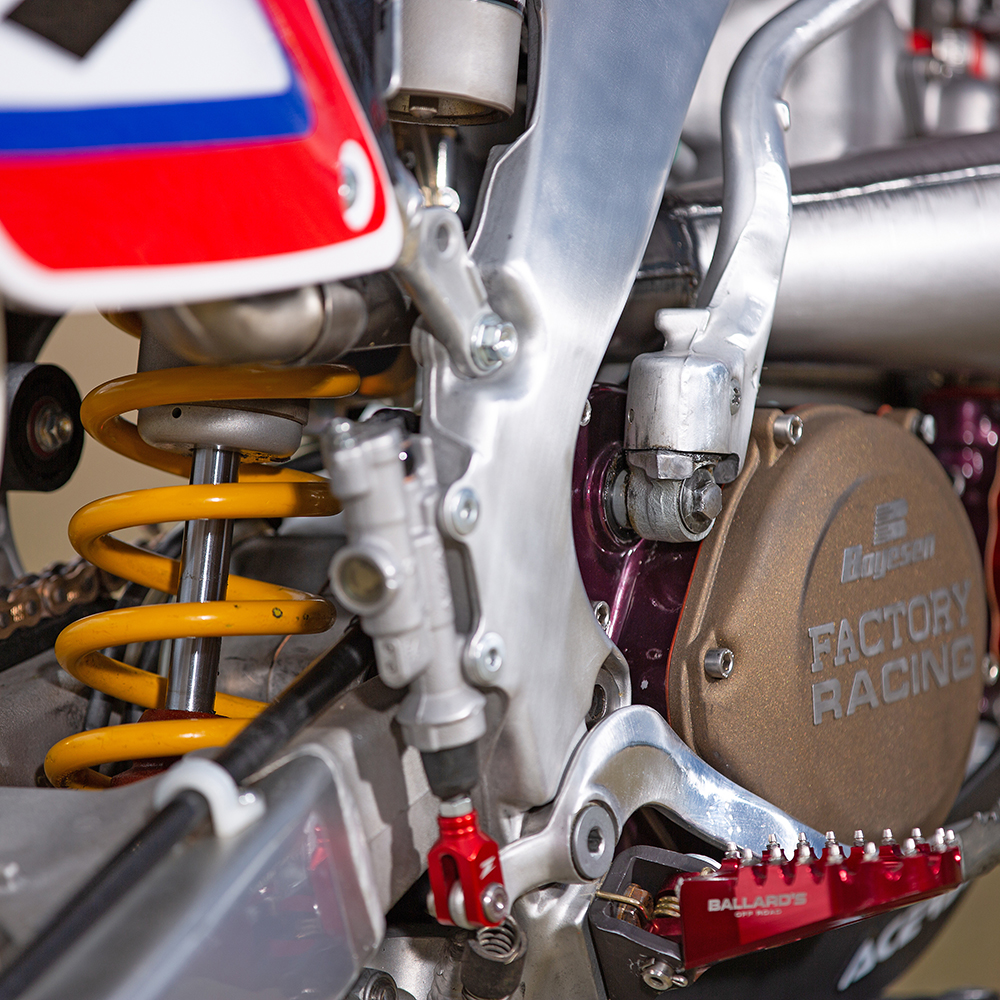

There’s a company called CP500 (conversionparts500.com) in the USA and they do a bunch of conversion kits for all sorts of year model Honda frames for 250 and 500 conversions. You just jump on their website and pick what year-model frame you have and they send you a kit that comes with a new billet Y-piece for the front of the frame, new frame rail mounts, exhaust mounts, adaptor plate for the air-box and a bunch of other parts that do vary a little bit depending on what frame you have. I also got some specialty parts from MSV Racing (msvracingpowersports.com) in the USA who manufacture some cool CR500 parts like the billet exhaust manifold and case saver.

It took me about two and half years to get all the parts I needed for this bike and when I had all of them here ready to go, it took me about three months to build the bike to the point where I could start it. I work a normal job from 7:00am to 5:00pm so I did this in my own time. I was getting up at 4:00am to work on the bike before work and it was around minus 4 C here in Armidale at that time in the winter.

I completely stripped the engine and installed new OEM bearings and polished gears. I had the cylinder rebored and fitted a new ProX piston. When I had everything ready, I rebuilt the engine and had it back in the frame on the same day.

I did it all at home myself.

I’ve always been mechanically minded and I got a certificate 3 in small vehicles from TAFE but I literally watched a YouTube video of a bloke building his engine to make sure I was doing everything right. I also bought a CR500 service manual and it was pretty simple really. I don’t know how I would go with a four-stroke. I think I’d be a bit timid doing that, but two-strokes are pretty good.

DETAILED BUILD

Everything on this bike is either brand new or refurbished. I stripped the brakes and fitted billet pistons and new seals and all bearing and bushes are new. The front brake has a 270mm Moto Master kit and I am glad I got that because the bike takes some stopping. I wanted as many performance parts as possible to withstand the power of the bike.

I don’t love mainstream stuff and I always wanted a raw finish exhaust and I wanted a works pipe from Bill’s Pipes but they don’t make them anymore. They’re as rare as hen’s teeth. Then I found this DEP pipe and Bill’s Pipes MX2 silencer. They work great together for power with torquey bottom-end, perfect mid-range and it still delivers that peaky power.

One problem a lot of guys have with fitting a 500 engine in an alloy frame is the exhaust. Most mass-produced pipes like the FMF sit too high and you need to cut the radiator to make them fit or even cutting the exhaust down because it can hit the front wheel. The DEP pipe is a low-boy style and clears the front wheel and the radiator.

I bought new Racetech plastics because I think they have the best color. Polisport plastics are a slightly different shade of red and I wanted as close to OEM Honda red as I could get. SKDA designed me a custom graphics kit for the look I wanted.

FIRST RIDE

I was damn-near positive I was going to break my leg the first time I went to start it up going off all of the horror stories I had heard. But I own an XR600R so I know all about kick-back. But when I kicked it over it fired up and revved to the moon because I had the throttle cable set too tight. It scared the shit out of me. It’s not exactly what you want from a fresh engine build.

My first ride I was shitting myself because I had no idea what to expect. I’d never even stood next a CR500 before, or even heard one run let alone ride one. The closest I had ever come was riding a 2008 CRF450R. I’d ridden a YZ125 and a couple of KTM300s but nothing like this thing.

I took it easy on the first ride and kept the revs low but it was a memorable ride. It handled exactly how I expected it to. It’s pretty wild. It turns on a sixpence and stops incredibly well. I run 14/49 gearing and it’s probably a bit too short, so I am going to try a 45-tooth rear. I’m running BP Ultimate 98 with Castrol A747 at 32:1 which is the recommended ratio in the owner’s manual. I’ve done a couple of hours on a flat track and ridden some hills and I love it.