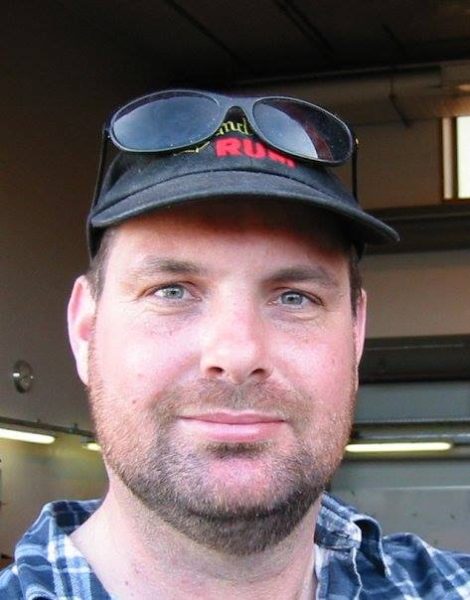

Buzz, the builder of this 1990 Honda CR250R, went through the usual process of being a keen motocross racer but had to give it up for more important things like buying a house and paying off a mortgage, but the bug never quite dies completely, it remains dormant looking a for a chance to resurface.

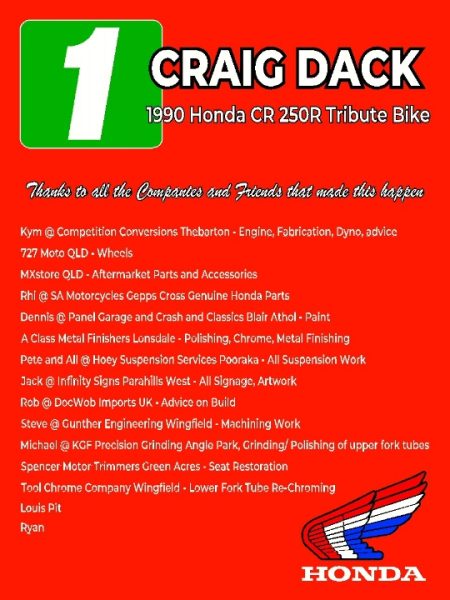

He tried road and adventure bikes for a while but his roots were in motocross so when it returned he decided on a restoration project. In his own words, “Many people restore a bike to OEM condition but I wanted to go one step more.” As a result, this Craig Dack tribute bike was born. The unusual thing about this build is it is a 1990 Honda CR250R but Buzz wanted to emulate Craig Dacks 1987 mount and we think he’s done a pretty decent job of it.

The 1990 Honda CR250R was found on Marketplace, and had originally come from the USA, bought by the bloke Buzz bought it from. It had been tarted up to look good in the sale photos but was in fact a bit rough, probably why the original importer decided to move it on. Buzz was in for the long haul though with no doubts about how much work would be needed and as a diesel fitter he had the trade skills to do it.

The 1990 Honda CR250R started okay on first inspection which indicated the engine was sound but the paint job on the frame was as rough as hessian undies, although most of the plastics were new. The right-side footpeg was missing the split pin the swingarm, linkages were badly worn and the triple clamps were stuffed. Buzz packed it up, took it home and installed it in his workshop to begin the long process of surgery.

The first thing he did was buy a manual, took a good look through it and worked out just what sort of build he was going to do – he was a man with a plan, a plan to stay organised. This is one area where a lot of builders get discouraged. They are all starry eyed at first with the thought of rebuilding a bike that may have been legendary in their younger years without realising the sheer amount of work involved. Interest wanes over time as these difficulties reveal themselves, so they take shortcuts and the job turns out second rate.

Not so with Buzz, who had a plan of attack worked out and he stuck to it. He did the job methodically and the end result is a piece of engineering artwork. All the liquids were drained as the starting point then the bike was dismantled into large components so each could be worked on separately. As he started stripping things he photographed each process and parts were grouped together and stored in plastic bags, and he printed off exploded diagrams from a Honda website, all with the intent of keeping the rebuild organised.

The first headache was when he couldn’t remove top triple clamp nut, even with a 500mm half inch breaker bar and yes, he was turning it the correct way. It was time to find an expert so he took the frame and triple clamp to Hoey Racing Suspension and even with heat it was a struggle to undo the nut. It turned out that the main bearing nut under the top triple clamp was totally stripped. An aftermarket one was over $700 but Buzz wanted to keep it as original as possible so tried find a secondhand one, but had no luck.

Then Gunther Engineering came to the rescue; they ended up running the smaller top thread down the length of the shaft and sleeved the top triple clamp to suit, so that was the first problem fixed but more awaited. Further hassles were revealed after sandblasting the frame revealed dents and flat spots underneath filled with bog, so they were cleaned out and TIG welded by Kym at Competition Conversions to bring the frame back to an as-new condition. As rebuilding the engine required many special tools and it wasn’t worth the expense for a one-off build so Kym was given that job as well.

The engine was opened up, the cases sandblasted, cleaned and then put in an oven to get rid of any oil or other residual contaminants. Next the cases were primed and put back in the oven, then a black top coat and back in the oven for another baking session, and the result was well worth all the time and effort.

Buzz collected as many genuine engine parts as possible and had them replaced, and most bolts were also swapped using a Pro Bolt kit. A Helicoil kit was also put to good use repairing the stripped threads in various places on the bike.

With the engine sandblasted, reassembled and painted to look factory fresh it was time to move on to the swingarm. More heat was required to make the seized linkages let go and some holes needed filling where somebody had added a side stand to the swingarm. A bit of TIG welding in the holes then some work with a grinder and that job was done. All the alloy parts were sent off to be polished and bolts were sent to be chromed, which was about a two-month turnaround. This process was done over three lots due to cost.

No doubt Buzz gave his local Honda shop parts people a job and a half tracking down and ordering the genuine parts he was after, and some took two months to arrive. The famous “slow boat from Japan” it seems. In fact, over the time of the rebuild, Buzz used the services of four different parts people due to holidays, changing employment etc. Inevitably some orders were forgotten or lost and had to be chased up a second time but Buzz sings the praises of all who helped him chase the many parts he needed both genuine and aftermarket.

As the resto progressed more evidence came to light of how the bike had suffered under previous owners, a not too uncommon occurrence on jobs such as this. That’s to be expected really as many old bikes get used as paddock bashers with minimal maintenance by kids who know no better until one day the bike just packs it in. It then sits in the back of a shed for years as the kids responsible discover girls and alcohol, until finally offered for sale in a shed clean-up. Then someone like Buzz comes along with the time and knowledge to restore things to their former glory.

Stripping the fork legs exposed large scratches on the top outer tubes while the lowers were badly pitted as some previous owner with little mechanical sympathy had been running the bike without the lower fork guards. KGF Precision Grinding took care of the various blemishes and they were re-chromed. Hoey suspension took care of rebuilding the shock and fork with all new seals and springs, so Buzz moved on to the brakes next.

Buzz considered using Chinese-made pattern parts but stuck with the OEM brakes due to quality; you don’t want to discover a brake problem in the first corner of a moto. That could not only be embarrassing but potentially damaging to both rider and bike.

Both master cylinders had signs of wear so were re-sleeved back to original size with stainless sleeves, then the calipers were cleaned and treated to new pistons and seals as well as braided hoses. The original wheel hubs were restored then sent to 727 Moto to be drilled for oversize stainless spokes and gold Excel rims. Next the frame was painted in two-pack and the shock spring powder coated.

The frame and seat colours had to match and Buzz was having trouble identifying the frame paint colour as nobody he approached from Honda – or even Craig Dack himself – knew the name of that particular shade of blue. The donor bike frame was white so a colour match by a good paint mixer was out of the question as well. Then Buzz’s mate Dan who had built a 1987 replica himself suggested a solution. Find the seat vinyl as close as possible to the original colour, then mix the paint to match, problem solved.

Things were starting to go back together by now, the bent radiators were replaced with new ones and painted black, and an OEM replica handlebar was sourced from the USA. Gouges in the tank were too deep to be sanded out so needed to be bogged up and then the tank was spray painted. After all that and then fitting a DEP Pipe and muffler, it was off to the dyno for a tune.

A road tyre was fitted for the dyno session, and Buzz was chasing a crisp state of tune rather than outright horsepower. The original carb was reconditioned but then Buzz found a Keihin 38mm Air Striker online and went for that, but when it turned up it was a Chinese copy and the cause of many headaches for Kym. One of the internal passages hadn’t been drilled out and some O-rings weren’t fitted properly and were leaking. After fixing all those problems it now runs like a Swiss watch and with Avgas in the tank it smells great too.

Image Details

Camera: Canon Canon EOS R3

Lens: RF14-35mm F4 L IS USM

f 4

1/1600 sec

ISO 160

Credit: Marc Jones/Foremost Media

Date: 4 May 2024

After 15 months of work, Buzz took the finished the 1990 Honda CR250R to the ProMX at Gillman for Craig Dack to see and sign. It got a lot attention from the race teams and other people over the two days which Buzz says was a bit humbling. Craig was more than happy to sign the bike and was very impressed with it.

Dare we say Buzz got a buzz from the overall experience?