Handcrafted Italian TM motorcycles are made with pride in the company’s Pesaro TM factory. TM lives and breathes racing with a heritage that dates back to 1976, with the company’s inception brought about by two friends who shared a passion for motorcycle racing.

Italy has been the birth place of many high fashion brands like Gucci, Armani and Prada, and in the automotive industry Lamborghini, Maserati and Ferrari. The Italian motorcycle industry is no different, with many well-known high-end brands like Ducati, Aprilia and Moto Guzzi.

Another Italian brand that many will be familiar with that hails from the coastal town of Pesaro is Benelli, which started out as a family owned motorcycle brand that was an innovator of many modern designs in the motorcycle industry, and over the years it supported Aussie riders like Kel Carruthers and Peter Goddard in the World Championships, with Kel winning in 1969.

Fifty years later, Pesaro is still the home to a high-end motorcycle manufacturer in the form of TM, who is still pushing new design initiatives in the pursuit of making the best competition motorcycles possible. Unlike many of its rivals, TM is not producing street bikes or scooters, but is solely focused on building competition motorcycles to the very best of its ability. With its focus directly on racing it has developed a system where it is able to produce more than 90 per cent of the motorcycle in house in its TM factory in Pesaro.

While having a presence in Australia, TMs are still very exotic – unique and beautiful motorcycles that are well built and covered in plenty of fruit, being finished off with parts from Circuit, HGS, Scalvini, KYB and Excel. Over the years we have seen many Australian riders like Jake Stapleton, Josh Green and more recently Wil Ruprecht and Daniel Milner racing and having success on TM motorcycles. We have seen TM win races on the world stage in Enduro and Motocross, and prove its worth as a high-end racing machine manufacturer.

TMs are handmade motorcycles with the factory only able to make up to 1300 units a year; compare this with the 300,000 units the KTM Group sells in a year and you can easily see why TM’s presence is so small. For the future TM has invested in larger CNC machines and expanded its factory with the short-term goal of making 5000 bikes a year, and a long-term goal of 10,000 bikes a year. To show off its new factory and equipment, we were invited inside the TM Racing factory so we could show the world how the last hand-built dirtbikes to be produced are actually put together.

The Front Door

You could almost mistake the front entrance to the TM Factory for something else. There is TM Racing branding out the front and a few trucks and vans parked around with TM stickers on them, but the front of this building is down a side street and would fit in one corner of the carpark at Yamaha Australia’s HQ. There are no neon lights and certainly no bells and whistles to catch your attention. It is simply a tightly packed factory in the middle of plenty more factories all fighting for space to make products for the world.

Through the front doors is a reception with a pink special edition TM on display, after which there’s a hallway full of office and meeting rooms leading to a single white door that opens up into a magical world of engineering.

This door will forever be etched in my memory. The feeling I got when standing at this door was like standing at the front gates of Disneyland; I could see the bright lights under the door and hear all the machining noises and it lit the excitement in me that burned right through the tour and beyond.

The Engines

Once through the door we immediately come across work stations where the parts and engines are built. There are mechanics at benches with buckets of parts around them assembling the engines. There is one guy that assembles the two-stroke engines and another that assembles the four-stroke engines. When you look around the room you see another guy sitting on a chair porting two-stroke cylinders and another assembling throttle bodies. There are rows of these work stations where all the mechanics have their specialities which they perform each day.

Each station has a different task and a different pile of parts. One bench will have all the engine parts stacked around it and another will be covered in shock parts. Everyone in this department has a smile on their face and gives you a nod and a wave as you pass by, or they grab you and pull you into their work bay to show you what they are doing. There are no machines in this area, just mechanics and their bare hands performing the tasks that machines and robots would do in most other factories. Even the guy who assembles and builds all the official racing engines has a bench mixed in amongst everyone else. If you look around enough you will even notice karting engines being built; TM Racing is a major player in karting engines around the world.

Machining

Further back in the factory are the machining rooms were enormous CNC machines run full time pumping out parts. There are massive boxes full of cast parts waiting to be machined. There are heads, barrels, throttle bodies and basically anything made from alloy or steel being cast or machined here.

TM prides itself on the fact that it makes more than 90 per cent of its motorcycles in house. It would be easier to employ an Italian company like Dellorto to make its fuel-injection systems but instead TM makes all the electrics itself and machines the throttle bodies. It’s all about doing it the TM way, to the best of its ability, not making it easier.

I’ve seen a lot of different machining and been in a lot of machine shops but the pride the workers at TM have in their workmanship makes each finished part look like a jewel. TM could get away with much cheaper manufacturing by using more cast parts, as casting parts is a cheaper process and doesn’t waste anywhere near as much material, but it would rather use the process that gives the strongest, best quality parts rather than cutting costs.

Also located in the factory are several polishing drums which parts are loaded into and covered in a media. The drums then vibrate for several hours and when the parts come out they look perfectly polished. This is done with transmission and many engine parts, as well as triple clamps and any other parts that need to look aesthetically pleasing.

One big thing about TM’s machining process is that the factory is very open and the raw parts are not covered in machining oil or glad wrap as there is no need to do so – the weather here is so temperate all year round the parts do not corrode. Another thing of note is that the research and development and engineering departments are set up right next to each other to ensure communication between the two departments is very quick and easy.

Further back again in the factory is a brand new machine shop that is being built. Not all the machines are up and running yet but these new machines dwarf the ones in the rest of the factory, and they are being installed to drastically increase the number of parts and motorcycles that TM will be able to produce over the next five years.

Bike Assembly

Bike assembly takes place downstairs where a row of hoists are set up and one mechanic will assemble one bike from start to finish, one at a time. All the finished parts are situated in order around the bike hoists and the mechanic will take each part he needs and assemble the bike to the finished product, and then sign off on his work with pride.

Also in the same area is the static dyno room where each engine is tested and tuned, as well as a chassis dyno that is used for testing and homologation. In these rooms one man decides exactly how many degrees of timing, as well as how much fuel each engine gets at each rpm and each throttle opening. There’s also a dyno that the race team uses to test and tune its official race bikes.

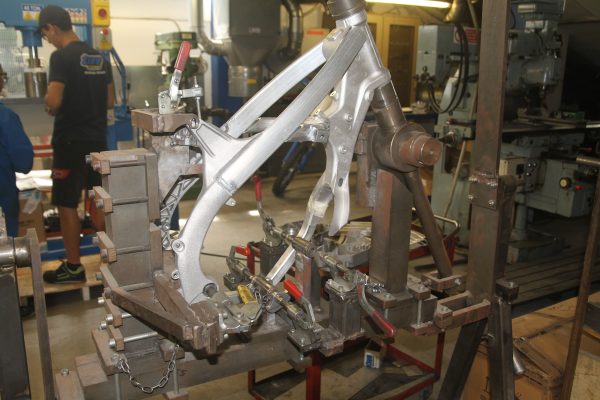

Also on this floor is where all the parts of the frame come together, to be welded into one frame. One man clamps all the forged and machined parts together and then welds them all into place before heat treating the frames. The process of hand welding as well as using cast, forged and machined parts means that the frame can be deigned to flex in certain areas while being rigid and strong in others.

A 125cc machine is built in as little as five hours but it takes one mechanic up to two days to build the four-stroke models. It’s possible to special order models with different parts like shocks, clutches or wheels, so this is also where these special parts are fitted.

Each mechanic does everything from bleeding the brakes, wiring up the electrics and adjusting the chains. They start out as a frame on a motorcycle hoist and are rolled off as a complete motorcycle. Each person that has a hand in building these motorcycles has a sense of pride in the finished product.

Once the bikes are built then they go to another section where they are stripped down and packed into boxes to be sent out to the world.

Wrap Up

More than 90 per cent of each TM motorcycle is made in the factory in Pesaro, Italy by TM Racing. There’s no cutting of corners or trying to build the cheapest motorcycle to maximise profits; TM is simply trying to build the best motorcycle it can… and this can be clearly seen in the factory.

Where CNC parts are preferred TM will use CNC parts over cast. The frames have several different sections all welded together that takes time to produce, as well as extra machine costs, and rather than employing other companies to make its electronic parts or fuel management systems, TM does it all in house.

The system works well, all the parts are machined and made on site and then sent to their allocated sections for assembly. The engine parts go to the engine department, the suspension goes to the suspension department and the wheel parts go to the wheel department. Once all these components are finished they wind up in the bike-assembly area where a mechanic starts with a bare frame and assembles the bike from scratch, all the way up to the finished product. Then the motorcycle is passed through quality control and then boxed up to be sent out to the world.

The whole process is old school and TM believes it can produce up to 10,000 units a year this way. The workers in the factory are all friends and family, and all take a great deal of pride in their work, with no plans to change the production process now or anytime soon.

When you look at a TM just know it was built by someone’s father, son, uncle or brother, not a robot on a production line.